I’m repairing a free-standing antenna tower (Wade DMX). Replacing the mast support brackets. Removing the rivets was surprisingly easy… so it seems the manufacturer uses aluminum rivets. That was a bit of a surprise, since I would expect a corrosion problem doing that.

Now I’m a bit puzzled. I can go on and on about aluminum rivets in aluminum structure (aerospace stuff) but now that the problem is reversed, in a steel structure this doesn’t seem right. Should I have expected steel rivets here?

I have lots of “aircraft” style rivets here of many aluminum alloys and have nice coatings - though none the right size for these holes. Since I’ll be getting more rivets to finish the job, is there a particular aluminum alloy type to be used here?

In the pictures below, no sign of corrosion at the rivet holes. There’s plenty of corrosion elsewhere on the tower (hence the repairs). Somehow the galvanized finish has been worn off in many places, but all the joints are fine. Is that due to a particular aluminum rivet type that was used? This tower is about 20 years old.

I find it surprising that aluminum rivets were used in a steel structure. It is not something I would have specified as I would have expected significant corrosion. I am curious as to why this was not found to be the case.

Me too.

But what would you DO if you wanted to know?

My go-to materials warn against this fastener-substrate combo.

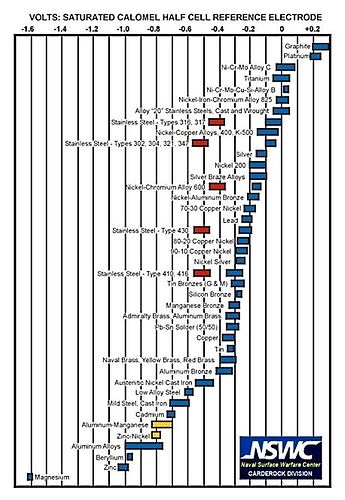

Look at a galvanic series chart with aluminum with manganese (Al rivets), zinc (galvanizing), and mild steel.

All 3 are very close to each other, so the potential to corrode is low.

The contact area is low too.

Since no corrosion is visible, I assume the assemble stays dry most of the time, so the presence of an electrolyte is low too.

So low-low-low, using Al rivets in this application doesn’t seem high risk to me, plus the ease of installation and deconstruction of Al rivets is much easier than steel rivets.

This is a very riveting topic!

Thanks Latexman.

My research on this has been curtailed by my home computer (which has the answers in it… somewhere) being inside a nonAC house in a heat wave. In my forced time outdoors I am just proceeding with the repairs.

Thanks. Yes that’s where I was going with this.

Your chart is related to a more comprehensive MIL-standard on the subject: MIL-STD-889 which is “owned” by the Naval Air Warfare Center. My copy of the STD and the related standards gives me this information and more about recommended coatings for various metal combinations.

The bare aluminum rivet (which is anodic) used in steel (which is neutral-cathodic) can be installed bare in some conditions (free of salinity or extended wetness) but that is the last choice among many more preferred options.

I’m getting set up to re-install rivets. I’ll use a type which normally has a chromate coating (MIL-DTL-5541) and drive them “wet” with a dab of paint. I might skip the paint if there’s a lot of squeeze-out of sealant between the two mating parts.