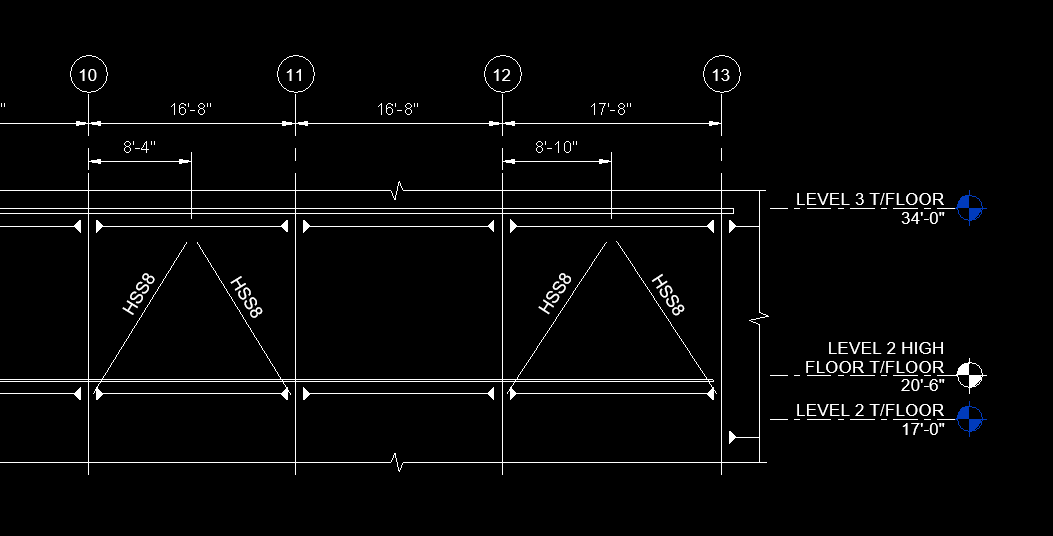

I have a building that requires progressive collapse mitigation in the design. The criteria is that any single perimeter column at any level can buckle under a blast load along with any vertical braces that attach to it. It allows for moment connections to remain so that the beam supporting the floor or roof above spans over the buckled column as one continuous member. Attached is a view at the 2nd to 3rd level for example.

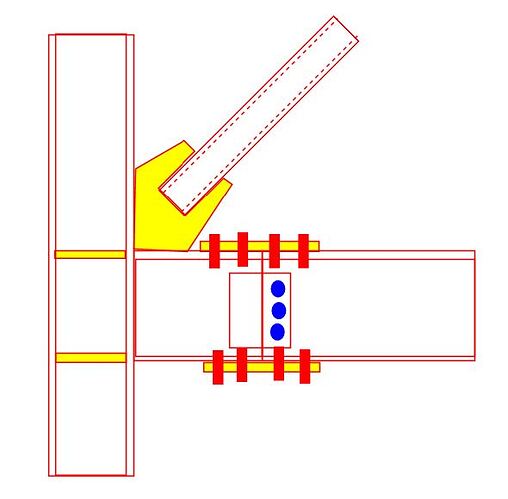

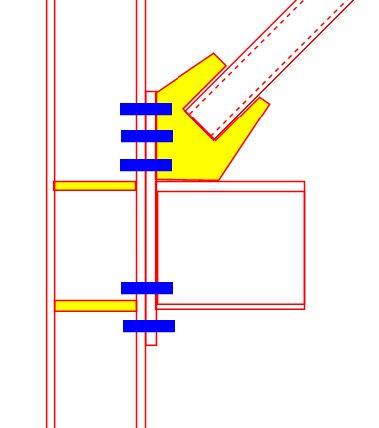

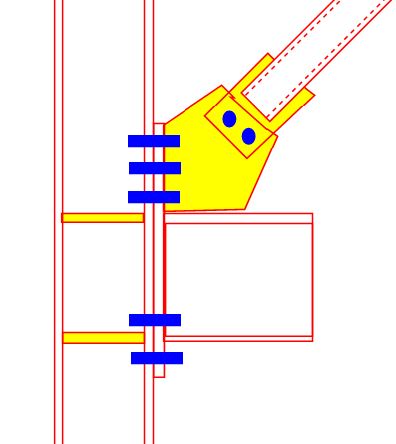

However, I would like to use vertical braces where possible to better control the wind and seismic drift. This is creating joints where the braces and moment connections come together and I have always avoided this in the past. Any advice on making this situation work (bolts versus shop weld locations versus field welds)? Or should I just avoid the braces altogether? I will be designing and detailing all the connections.