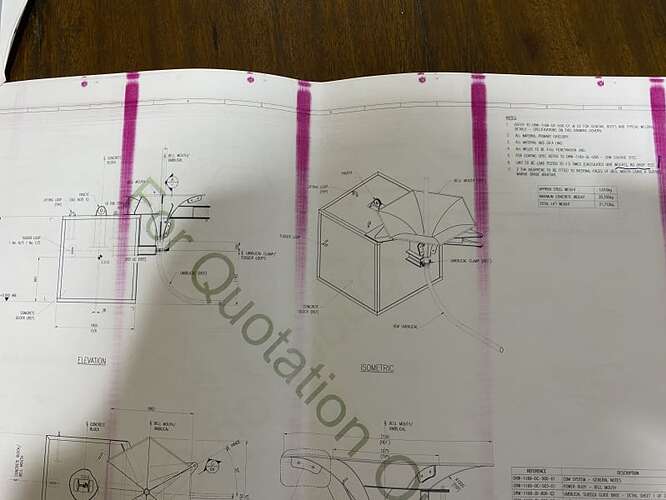

This is my first posting in this forum . I am a Metallurgist and I have a RFQ for a concrete sinker block with bellmouth and lifting attachments.

A concrete block is to be cast with weight measuring upto 20700kgs ( pl see a image of the arrangement).

My concern is about the concrete density 3tons/cu.m . Literature states that density of mortar is 2.400 tons/cu.m

Is there anyway we can achieve this requirement of 3tons/cu.m?

The only other requirement is load test 1.5X the calculated weight.

Thanks in anticipation.

A brief google for the term “high density aggregate” found the article here: article on high density concrete

which has this in its introductory section:

“Some of the natural minerals used as aggregates in high density concrete are hematite, magnetite, limonite, barite and some of the artificial aggregates including materials like steel punchings and iron shot.”

Seems like a foundry guy like you may have access to some of those ore rocks, or could produce a variety of shapes/chunks/foundry off-cuts and sprues to supply to the concrete mixer.

Also this site: (concrete.org website)

1 Like

Thanks Ben. I will try to use some of the foundry offcuts and wastages. Ore rocksI am not too sure of sourcing it in Nigeria.

Trick lies now in dispersing it uniformly inside the volume !! I have a COG condition to satisfy too.

Thanks once again. Engineering fraternity is a great source of knowledge sharing and cooperation. Hope, tradition continues.

I think there is a big taconite(?) (edit: hematite, and it’s several mines) mine up in Mauratania, the one they built a train line across the desert to ship the ore out on…trouble being that the unrest in West Sahara disrupted the line…but I think it’s back in service now.

checking wikipedia: it is

As far as dispersal - I would be talking to a local concrete mix supplier about desired size and shape of pieces. Probably not a typical concrete mix, though. Hope some marine engineers are around who can weigh in on this. Get it? Weigh in? Sigh…dad jokes are my downfall.

1 Like

@arunmrao Here is a “trick” that should solve the density, heavyweight aggregate availability, necessary steel reinforcement, and center of gravity requirement, all a the same time:

-

Concrete @ 2400 kg / cu. meter (2320 kg / cu. meter is more accurate for normal weight plain concrete).

-

Reinforcing steel @7850 kg / cu. meter.

-

To obtain density of 3000 kg / cu. meter, design the block with about 88% concrete and 12% reinforcing steel.

Will take careful thought to determine proper size, spacing and distibution of the reinforcing steel, but my preliminary calcs indicate doing this, while very unusual, is reasonable. There is no one “correct answer”, many combinations of rebar size and spacing should work. Considerations will include adequate spacing of the reinforcing steel to allow concrete placement, and cooling of the fresh “mass concrete”.

2 Likes

Thanks for showing me the way. I was preparing for using 16mm diameter rebar mats to increase the weight, but did not proceed with calculations.

This morning I can go ahead and complete the RFQ.

Learning never stops even at 66 years of age!!

I was thinking about that idea last night, but having the included iron structure be a casting that would free stand inside the formwork. Probably not worth the effort vs. welding/tying up a rebar cage.

1 Like

Thanks Ben. Last night I was just visualizing the various possibilities of adding iron scrap. To day being the last day for submission of commercial offer, I had to convince the team and prepare the Commercial offer.

Thanks once again. I shall come back with more questions if my bid is successful.