QUESTION

I have a question about connecting timber roof beams.

Since its pretty common, that roof beam consists from more than 1 element (span of several meters) we have to connect its elements.

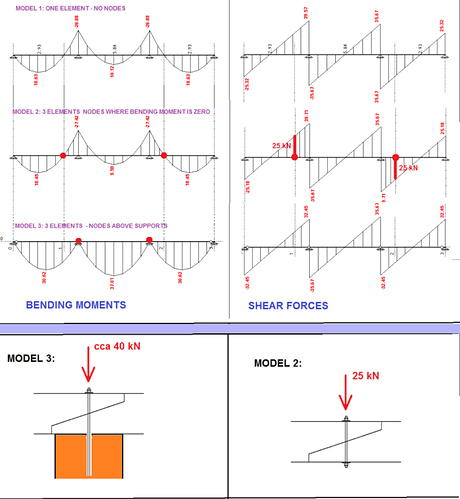

So if we have 3 elements we can connect them at/above supports (walls/columns)- MODEL 3 in picture. Other option is to make a connection at a point where bending moment diagram is zero - MODEL 2 in picture.

I found out that in MODEL 3 there are always bigger deflections which often causes problems and demands bigger beams. MODEL 2 has much lesser deflections at same load and geometry…

But what Im wondering about is what do we do about shear forces that acts AT connection (node) in MODEL 2?

How do we control it on shear force? In picture we have a shear force of 25 kN there…Element is 20/24 cm, timber C24.

I have never seen any project where engineer made a control of connection like this for a shear force. Why is that?

REPLIES

molibden

Model 2 is a typical connection in my area. You turn your connection in a way that the bolt is under tension. Turn it around and you can get splitting in both timber members. So basically you need to design the bolt and the washer so it is big enough based on compression resistance perpendicular to grain. Most of the time there are two bolts.

I design such connections. Maybe because I am more of a wood guy. Other engineers that mostly do concrete probably don’t go in so much trouble and let the carpenter do their thing.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=421242

Above is a snippet.