How do you calculate actual flow rate of Fuel Gas from the flow meter reading?

In our process plant we have Fuel Gas FTs which gives us reading in Nm3/hr and we want to calculate from this reading actual fuel gas flow taking into account temperature, pressure and specific gravity corrections.

Which is the most accurate formula for calculating flow rate? What are the best practices followed by other refineries in order to calculate the fuel gas flow, do they apply temperature and pressure correlations? Pressure or density which is better to take in .

Some time the actual fuel gas link with LHV to more accurate.

My first preference is to study the documentation from the manufacturer that usually comes with the flow meter, and to supplement that with technical documentation from their web site. If that does not provide what I am looking for, I call their technical support and ask to speak to their expert on that flow meter.

By the way, what kind of meter? Who made it? Model number?

What value and units is your LHV of fuel gas?

The Unit of LHV is Gcal/kg

Volumes stated in Nm3/hr are usually volumes measured at standard conditions of 1 atmosphere pressure and 273.15 deg Kelvin (usually but not always … there are many definitions of standard conditions).

You can convert Nm3/hr to actual m3/hr at any other pressure and/or temperature by using:

P1V1/T1 = P2V2/T2

where:

P = absolute pressure (i.e., gauge pressure + atmospheric pressure)

T = absolute temperature (i.e., deg Kelvin or deg Rankine)

V = volume or volumetric rate (i.e., m3/hr)

Make sure that you ascertain the standard conditions that were used to define the Nm3/hr (i.e., V1) and use them for P1 and T1.

Wikipedia has an excellent article on gas laws. There you will see the ideal gas law:

PV = nRT

To convert from volume to mass, one needs a density or specific volume. With the average molecular weight (M) of the fuel gas, one can derive as follows:

PV=nRT

n/V = P/RT

density = nM/V = PM/RT

You could calculate the N density and multiply it by the Nm3/hr to get mass flow rate units, or you could calculate the actual density and multiply it by the actual m3/hr to get mass flow rate units.

There is no increase in accuracy in my opinion, one just has to ascertain the conditions and convert consistently and correctly.

It obvious dear.

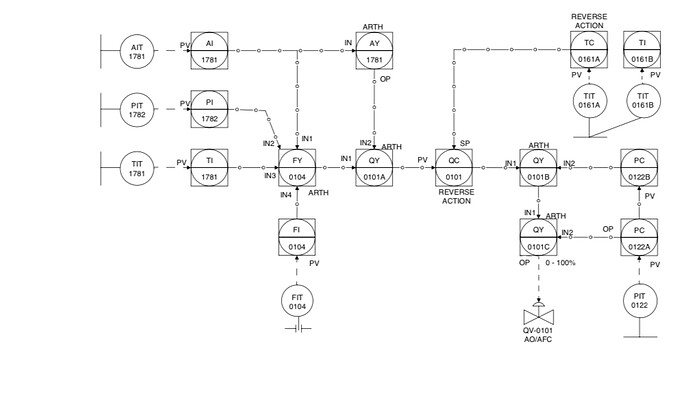

.analyser specific gravity(AI20) ,out put of Fuel gas pressure PI023(kg/cm2g), Temperature of Fuel gas TI012 © and Fuel gas flow rate FI031(kg/hr) goes input to Heat rate (Fuel gas flowrate compensation block Arithmetic control block (FY015).Another out put from analyzer goes input to another block (AY024)calculates the LHV of the fuel gas based on its composition . The output of this block goes to Arithmetic control block QY013which is calculates the actual heat rate of the fuel gas stream plus input from.if only output from analyzer (AI20) goes to to FY015 it work fine. Why the put another output from analyzer to QY013 and why the called LHV because from same analyzer there is any difference?

I am not confident I sketched the diagram correctly from the description. Can you upload a sketch?

Can you read the DCS code? I do not have much experience with DCS code, so I doubt I could read the DCS code. I am process engineer. So, my best guess follows.

FY-0104 is calculating actual flow rate. From AI, it calculates MW. Then, combines MW with P, T, and F (Nm3/hr) to get kg/hr. (Maybe this calculation with 4 inputs used up the capacity of the block, such that AY-1781 is needed to complete the calculation.)

AY-1781 calculates LHV in Gcal/kg.

QY-0101A calculates actual heat rate.

But from analyzer it self to inputs one is given to FY0104 and another to AY 1781.

Why like this ?I think enough one input to FY0104

Yes, it seems to me all the calculations could be done in one, i.e. FY-0104. But, for some reason the designers used two, i.e. FY-0104 and AY-1781. Why? Did the number of inputs, 4 into FY-0104, reach the limit? Was it a memory limit of FY-0104? Maybe one input cannot be used in two separate calculations? I don’t know; I am guessing. There must be a reason. As I said, I am not DCS software experienced.

I have been assuming this is an existing design. Is it, or is it being designed now? Or, a re-design is underway?