Since we have a new section on SimpliEngineering, some of my research on DIY EV’s might be worth sharing.

I am still far from starting an EV build of my own. But I’ve been thinking about it (a lot) for many years. I’ve been collecting info from the major manufacturers, and from DIY sites like https://www.diyelectriccar.com/ and the “EV Garage”. I put in data from the battery pack size, motor power, range and so on. I was wondering how the DIY projects stack up against the major auto-makers. SURPRISINGLY WELL as long as we compare apples to apples.

To keep my info organized, I put it into a spreadsheet. That spreadsheet grew into several tabs with product comparisons of the various necessary things, like batteries, motors, controllers, etc. Soon after that I was able to make a performance prediction tab, where I could enter some basic goals (range and mass) and get an approximate battery pack and motor size.

(sorry, the link didn’t work - see below)

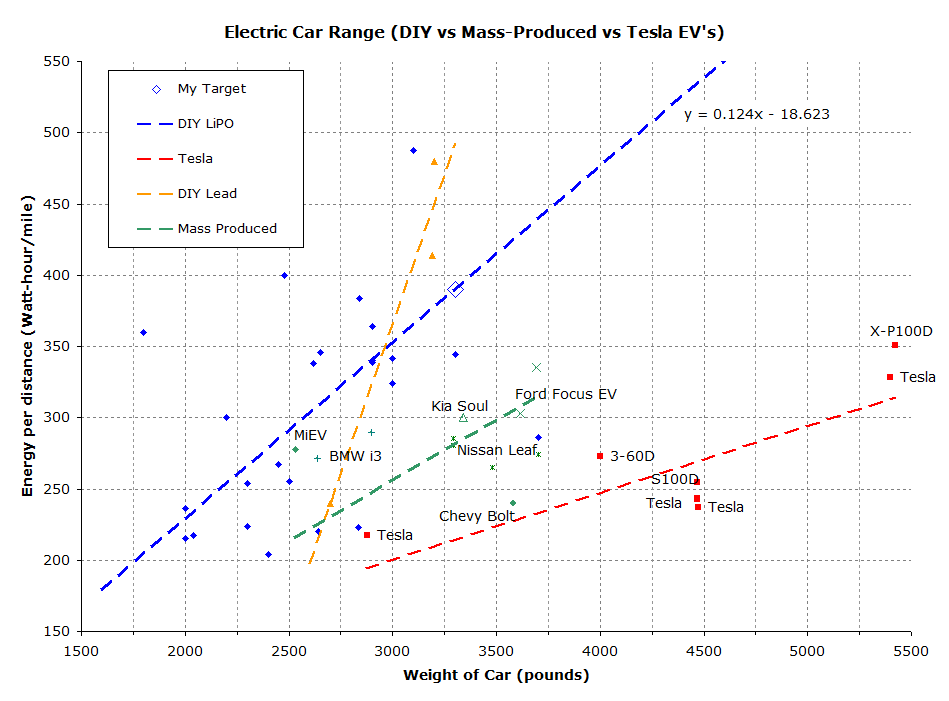

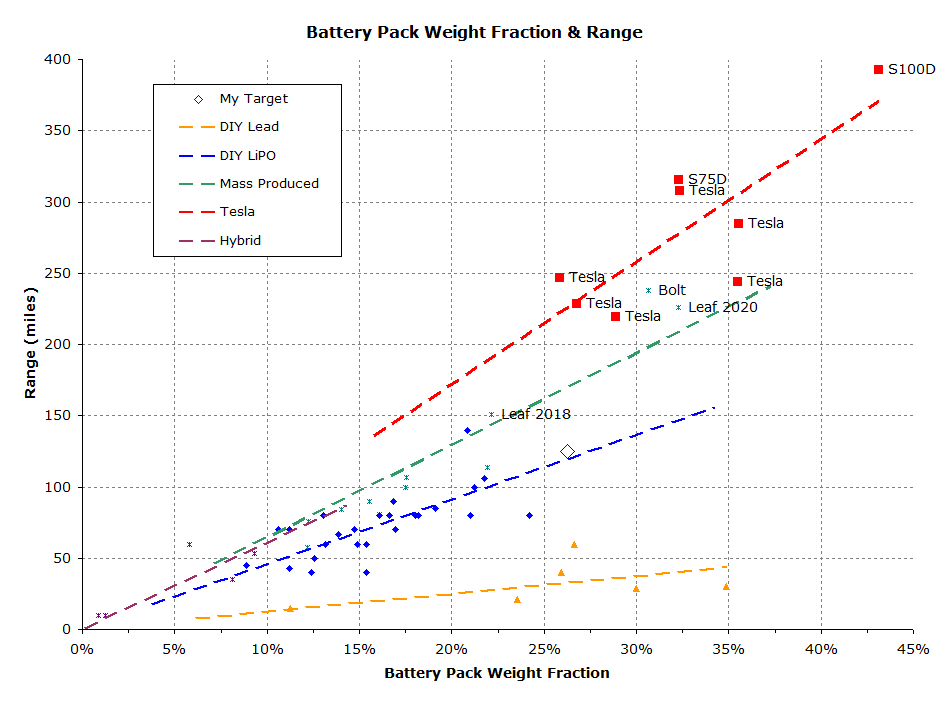

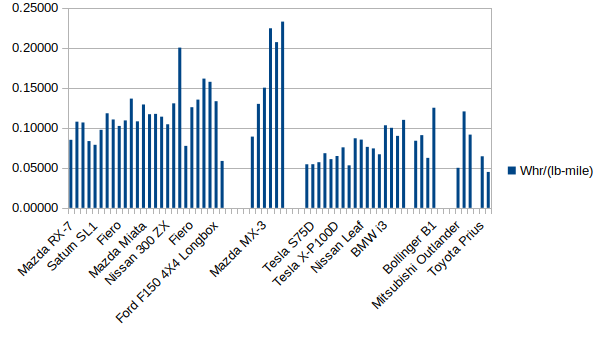

I compared groups of EV’s, looking for trends and similarities, and I found many. There are four distinct types of pure EV:

- DIY lead

- DIY Lithium

- Production Lithium EV’s

- Tesla (a class of its own)

A comment about the data:

Getting good, reliable data is hard. I have to rely on the claims of builders, but you know, we’re not all scientists. At the same time, we should not believe the range values from the OEM’s, either. BMW has been caught exaggerating about the i3. The old Leafs are disappointments. I’ve gone back and corrected claims made in the past that didn’t hold up in the real world. And if anyone finds any errors or would like me to consider something I missed, I’m all ears. There’s some scatter in the data, but actually a lot less than I expected.

Trends for each “technology” are definitely grouped. They also tell a bit of a story of technical progress as EV’s become more capable. Lead is obviously the past, and here’s a clear illustration of why. To get any range requires an enormous amount of battery mass, but soon mass of the the loverwhelm the mass of the car.

Hybrids (I’m not finished this part) can be compared to production EV’s as long as you look at the all-electric mode of operation. It’s really hard to get good information about the pure-electric function performance of some hybrids. I have to rely on magazine reviews in places.

Close together are the DIY and production EV’s with Lithium batteries. The production EV’s have a slight advantage, but there is considerable overlap. It is clear that the DIY builders have access to technology that is similar to the technology being used by the major automakers. Note that I haven’t included any DIY builds that use production vehicle drivetrains or batteries. That could be a 5th technology group but it might also have been confusing. So no DIY Tesla drivetrains in a Mazda Miata in these graphs, for example.

Then of course, there’s Tesla. They really stand out, although I must give a shout for the proud little Chevy Bolt which somehow slipped into the Tesla pack by these measures.

Overall, I am very impressed with what DIY EV builders can achieve. Their results can equal and in some cases even beat the major OEM’s, which is just amazing

Maybe someday I can join the club!