SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=442961

The above URL contains the entire discussion. Below is a snippet.

QUESTION

How to sharpen a drill bit?

REPLIES

Berkshire

A center drill bit looks like this attachment :

https://www.micromark.com/4-piece-Center-Drill-Set…

It is common when drilling a hole where you do not want a burr to set the depth so that the wider part of the drill just takes off that burr and leaves a slight chamfer. Sometimes a common drill bit is modified to get the same effect instead of using a center bit.

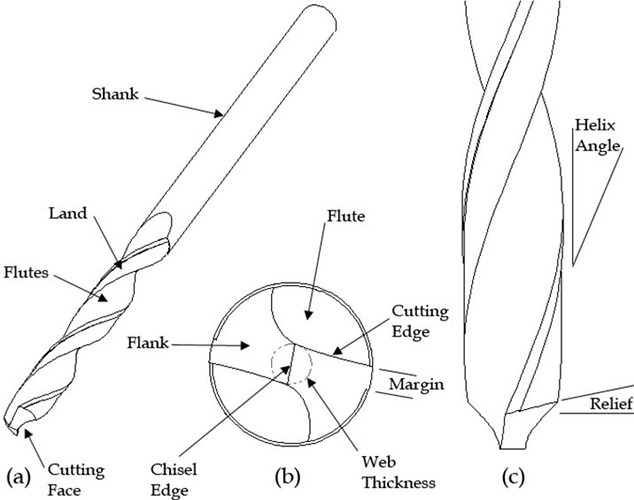

Now regarding the wear on the sides of the drill, after you have drilled several holes, not only the cutting edge of the drill , but also the sides of the drill will wear. this is the area called the margin in the attached picture, when that is worn you cutoff that piece of the drill to known good material . With regard to the web thickness this is the area in the circle in the picture. After the drill has been sharpened several times, because of the taper I mentioned before, this gets bigger, making the chisel edge wider. to make that chisel edge narrower a small amount of material is ground from the back of the flute. This lowers the pressure needed to make the drill cut.

https://i.pinimg.com/736x/21/e8/84/21e884ff13f917e…

Here is a YouTube video on the subject. It is highly simplified and just shows the basics. This is sometimes referred to as grinding a split point. The technique enables more sharpening’s from a used drill. It also is used on new drills to reduce contact pressure and reduces wandering. Since English is not your first language, you may have to watch the video several times, this man has a fairly strong accent. The actual demonstration starts at 2.44 mins.