Any motor designers out there?

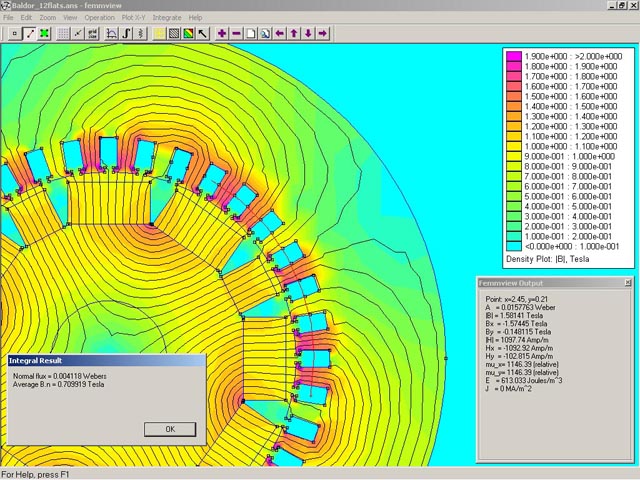

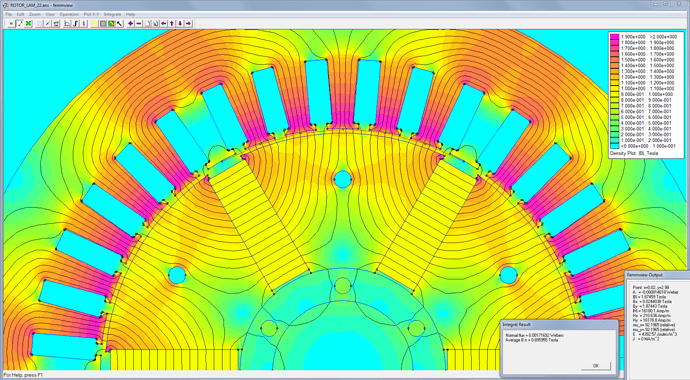

For many years I have been converting 3-phase induction motors into 3-phase self-excited generators by removing part of the rotor’s induction bars and replacing them with neo magnets. I’ve written extensively on the subject from a hobbyist perspective. Here in particular: http://www.sparweb.ca/3_Gen_MoCo/Baldy.html

I’ve done 4 of these conversions now, and I’m considering another, if a certain person I know commits to buying a custom wind-turbine from me.

Although I’m satisfied with the result - really have no reason to complain - I am interested in doing better. Neo magnets are expensive for one thing. The conversion is time consuming, and contains a lot of trial-and-error. There’s a point where I just throw a dart and hope for the best.

Are there any members that have a grasp of the details in designing the flux path in a motor with permanent magnets? Of course, there are lessons from the induction motor to be applied to this type of conversion, so I don’t want anyone to feel I’m not open to ideas or discussion. If you have heavy thick textbooks, all the better. If you did your doctoral dissertation on the subject, please pile it on, the more ODE’s the better.

This isn’t the first time I’ve posted on a discussion group about this subject. In the past I’ve encountered some confusion about what I’m trying to do, or advice to do things that are much more complicated that what I actually do, and have nothing to do with building what is, essentially, a BLDC motor/generator. I hope to stay away from those diversions but I do admit, what I’m doing is unorthodox. Hopefully you can trust me when I say that what I’ve built can contend with the best wind turbines that the NREL has ever tested, and that my goal is to understand why, and maybe do better. If that trust is hard-earned, I have written a lot on my personal journal site www.sparweb.ca and a forum dedicated to DIY renewables projects https://www.fieldlines.com/index.php/topic,149797 so maybe more reading there will help.

The alternative to these motor-conversions is, of course, to find nearly brand-new BLDC or similar generators in TEFC enclosures with fat bearings, 30Amp or more current rating and a linear V-N curve that can arrive on my back porch for less than 1000 US dollars. If you can find that (I’ve looked; it’s all trash) then of course this whole discussion is moot.