QUESTION

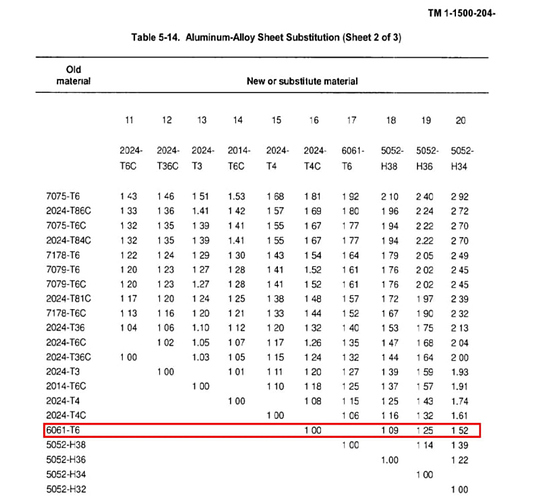

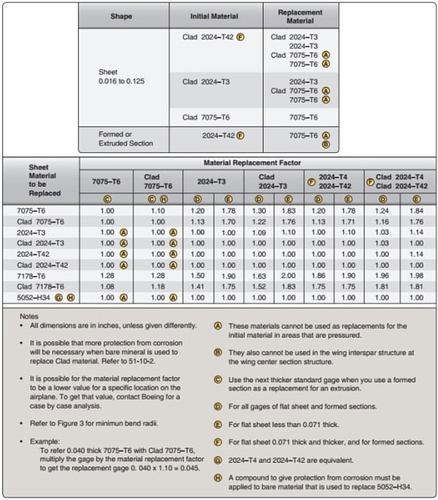

Many materials or material product forms used to manufacture or maintain the original parts on today’s vintage aircraft are no longer available or practical for reproduction to the original design data. To manufacture the needed parts requires materials or material product forms substitutions, such as substituting aircraft metals rarely used today with an equal to or improved material.I came across a technical manual (TM 1-1500-204-23-10)that had multiplication factors for various metals. Would anyone know who how they came up with the multiplication factors?

http://everyspec.com/ARMY/TM-Tech-Manual/TM_1-1500-204-23-10_CHG-4_54273/

See snippet from the TM and SRM in the attachment

REPLIES

SparWeb

Probably nothing more complicated than:

FTU (2) / FTU (1)

If they don’t give references for their claim then we can only guess. I would rather not attempt to reproduce the table just for the sake of confirming where it came from.

Most sheet-metal structures have a buckling failure mode. That won’t be affected Ftu as much as by Young’s Modulus.

Many tempered aluminum alloys have roughly the same ratio of Ftu / Fsu (tensile strength / shear strength). It’s usually about 60%. That ratio is not the same when comparing different tempers.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=461351

Above is a snippet.