The situation:

-

Hollow core planks got installed and then an RTU was dropped and smashed through a few of them.

-

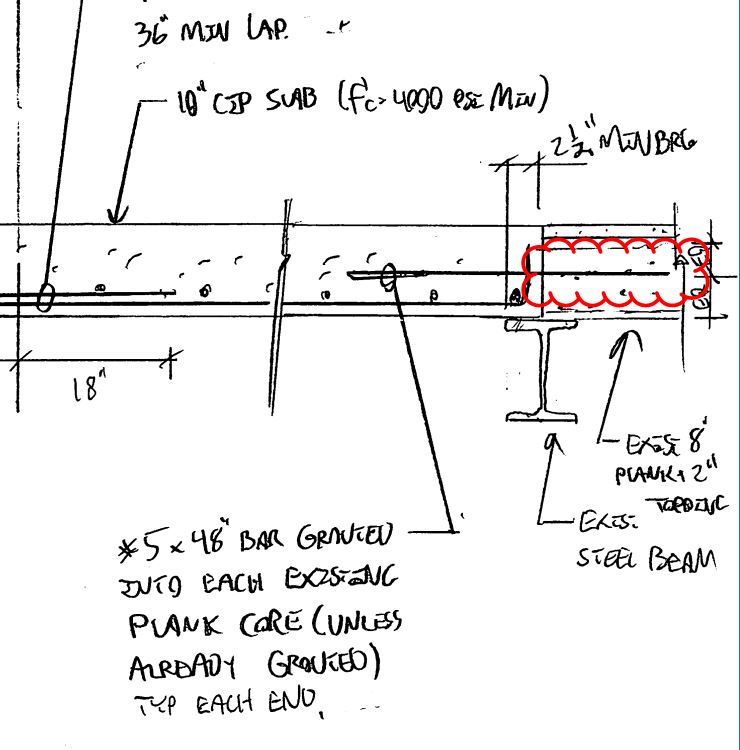

We generated the CIP repair detail show below.

-

The clouded dowels have three jobs in my opinion:

a) Nominal joint crack control (probably not very effective).

b) Nominal code integrity requirement satisfaction for precast stuff.

c) Anchorage of positive moment flexural steel at the supports. These are situations where you’ve only got about 3.5" of slab bearing and, probably, 2" or so cover on the upturned hooks. So not great for positive steel anchorage. I’d loosely considered the dowels as lapped to the positive steel in such a way that I could feel more comfortable with this aspect. Yeah, it’s an offset lap and all that jazz.

- This was installed with the plank cores grouted only 10" into the plank rather than the full, 2’ length of the dowels.

Function 3c is my only serious concern here. I worry that, with 10" bar development, the new slab will exert shrinkage strain on the dowels and, because they’re not fully developed, a bond failure may ensue and the dowels will be useless. How valid is that concern? This is a 15’ slab span so maybe the accumulated shrinkage might not be enough to exert much strain on the dowels?