QUESTION

I own plastic injection machine and make automotive cable parts

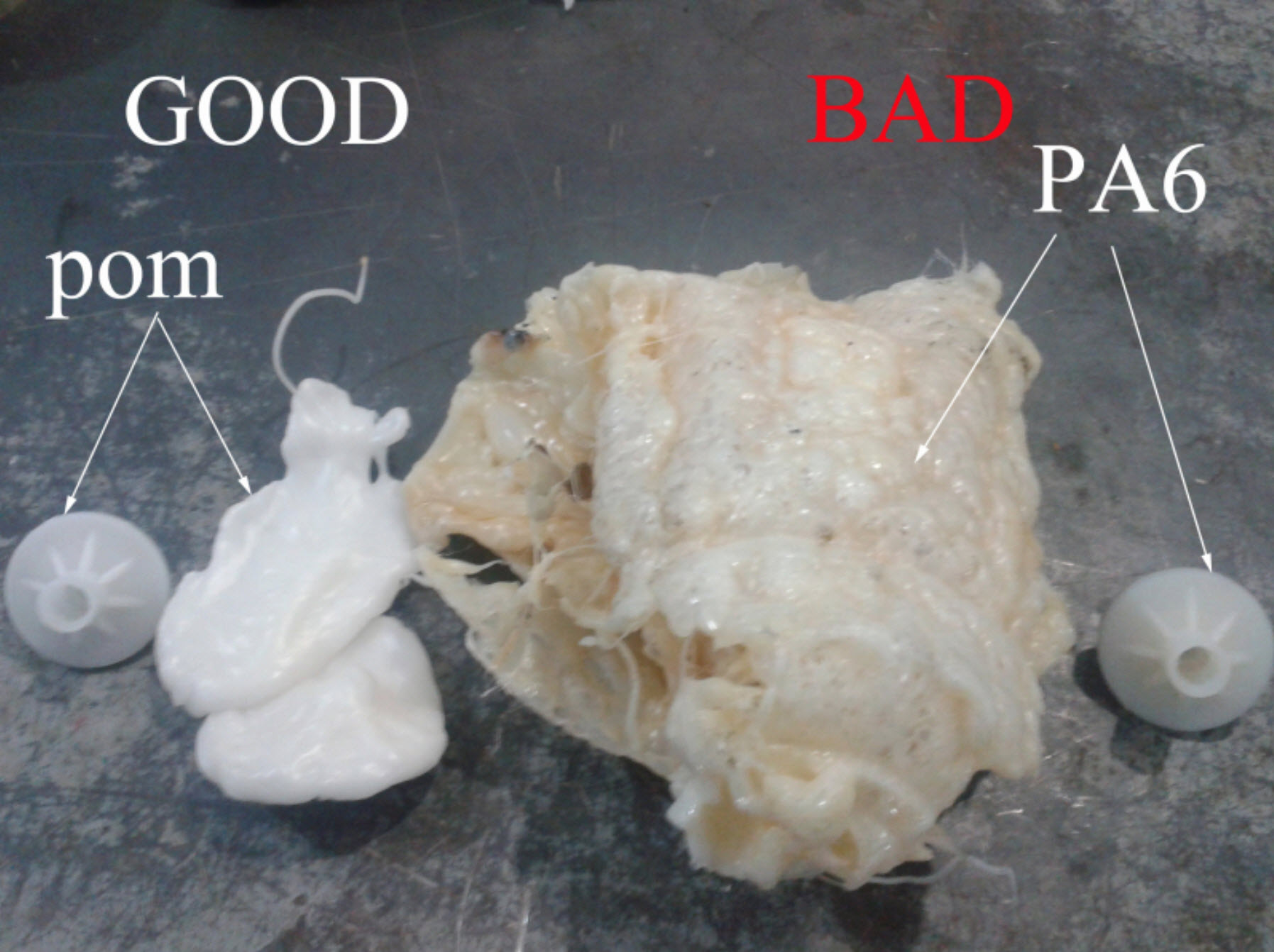

I used POM material and everything was good. Now with PA6 AND PA 66, there are problems.

See the picture:

The part formed containing bubbles, and I’d like a solution to this problem .

REPLIES

@Pud

PA6 needs drying for AT LEAST 4hrs @ 80°C. Start the time from when the bulk is actually up to temperature.

If still foaming, continue drying. I would suggest you dry for at least 8hrs until you know your dryer performance - if it’s just a hot air dryer, I would strongly recommend you invest in either a dessicant or vacuum dryer. You’ll soon repay your investment cost.

In a vacuum dryer, temp can be increased to 100°C - needs a vacuum to prevent surface oxidation.

NOTE: Even without showing foaming, moisture content can be too excessive causing brittle mouldings which look fine.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=401217

Above is a snippet.