Hello everyone,

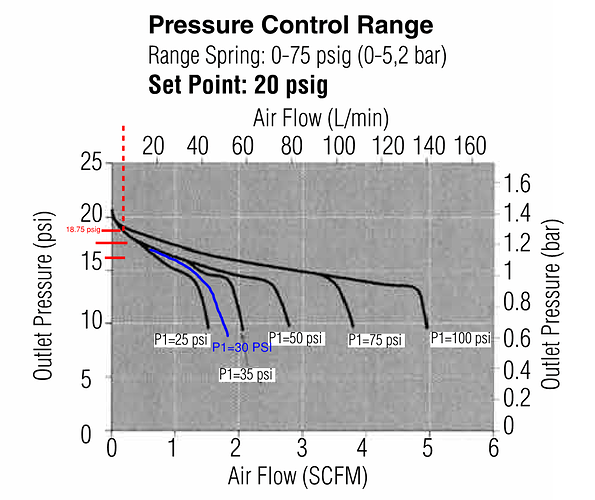

I’ve attached the regulator curve I’m looking at, and edited to include the points of interest. I asked the vendor to send me a regulator recommendation where the inlet pressure (P1) is 30 psig, the setpoint desired is 19 psig, and the outlet flow desired is 17.5 slpm or 21 slpm; I want that particular flow and pressure during flowing conditions. To me, the curve shows that an outlet pressure of 19 psig means a flow of ~10 slpm through the regulator.

I asked the vendor about the curve not supporting the operating point I need, and the vendor response is the following:

In regard to the JSRLFLP chart questions discussed in the email chain below, your approach for creating an approximate, interpolated curve for the P1 of 30 PSI proves on point.

However, it sounds as if you are treating the coordinate point you located on your interpolated curve as a reflection of the capacity limit of the JSRLFP when set at 19 PSIG, which would not be the case.Rather one should examine the entirety of the curve as that line indicates the Pressure/Flow capabilities and offset (droop) of the trim (Flow Coefficient, Cv) under flowing conditions. Droop remains an inherent characteristic of all self-operated regulators, and thus deviation from set point is to be expected as flow changes.

Based on your interpolated curve, it would appear that the capacity of the JSRLFP with a Cv=0.08 when set at 19 PSIG with an inlet pressure of 30 PSI would hover around roughly 50 SLPM.The JSRLFP with a Cv=0.08 can certainly handle the 17.5 to 21 SLPM capacities you mentioned in the email chain below. If your goal is to achieve the regulated pressure of 19 PSIG at the point where the flow is 21 SLPM, then, once installed, you would simply have to make certain to calibrate/set the pressure regulator to the 19 PSIG set point under that flowing condition.

The first bolded statement seems wrong because at 50 slpm, the outlet pressure would be around 9 psig, not the 19 psig I need.

I don’t understand how the second bolded statement sentence can be true - isn’t the curve telling me if the regulator is limiting the downstream pressure to 19 psig, then only 10 slpm of gas can flow through it? Also, if we stipulate the behavior the vendor is stating, then the pressure will rebound to some higher value during static conditions, which would defeat the point of having a regulator.

The blue line is my swag at interpolation between the 25 and 35 psi curves. I broke the space between 15 and 20 psi into 4 equal segments to make the minor gradations.