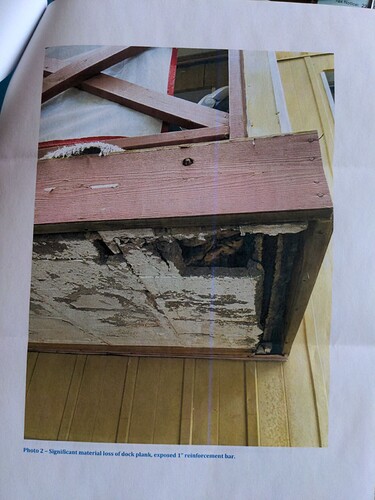

Hey everyone, I have a building I looked at and wanted to see if anyone else has come across this. It’s a 3 story apartment building with an exterior walkway at each floor cantilevering balconies at the front and rear. The floors consist of hollow-core concrete planks. Due to long term exposure to moisture there are cracks in the undersides of the panels and some concrete missing, where you can see corroded tendons, with some having even fractured. I’ve included some photos.

Front and Rear Cantilevered Balconies:

I had thought about cutting the panels off at the building and building new porches from the ground up, but I’m not sure that’s a good idea as it might affect the bonding of the tendons to the concrete and their development length. So instead I was thinking of keeping the cantilevered balconies in place and supporting them from the underside with steel framing. I think a reinforcing netting will need to be wrapped at the underside of the panel since I can’t quantify it’s capacity. Thoughts?

Walkways at the side:

I had thought about removing these precast panels at the balcony all together and replace with a wood or steel structure. I’m not sure wood is plausible, since it might violate fire code. Not sure if a fire rating is required at an exterior walkway of an apartment building. They build wood porches all over the place in Chicago so I’d think it’s ok but I’m unsure. In any case, steel might be a good option if replacement ends up happening.

I am leaning toward keeping the panels in place and supporting them from their undersides, having steel at the ends and midspan or third points of the panels and have a reinforcing mesh at the underside since we can’t quantify the capacity of the panels at the walkways either. I’m not sure of any other way to repair these.

Anyone familiar with this kind of repair?

Thanks

Not familiar with that kind of repair, but I would be concerned about ongoing corrosion of the existing reinforcement. If that could be prevented , then the idea of providing a steel structure below seems to be a reasonable approach. If the steel structure extends down to the ground, the foundation must be prevented from heaving due to expanding soil or frost.

Thanks…I am thinking it might be best to replace it all now. I can’t quantify the extent of damage and I think the cost of reinforcing the bottom with a mesh and installing steel structure with it’s own supports would cost the same as replacing everything. I just don’t want to run into the situation where it keeps deteriorating until eventually it forms more cracks and even the reinforcing mesh is not sufficient.

It might be well for Ron to chime in here too as he has more experience being in Florida, but from what I have experienced, once rust starts in reinforcing steel, it is just a matter of time before the member fails, regardless of any corrective measure taken to control the rust.

I would be concerned with the removal of the cantilever portion of the deck as it will affect the back-span capacity - that condition should be checked to see if it will be a problem.

I can see the covered decks as being a red-tag safety condition and would recommend remove and replace… and soon. I would look at replacing the failing hollow core deck with a vented, pressure treated wood assembly if possible - I do not know the framing scheme for the covered planking.

Just my 2 cents…

1 Like

I have been told if your concrete overlay is at least 2 to 3 inches then there’s less chance of moisture induced rebar corrosion. I would coat it with epoxy that’s another way.

The problem has probably been addressed by now. It would be interesting to know what was actually done.

1 Like

would love to hear about an update. I have a similar problem with my 10 inch hollow core precast concrete with eight strand or 1 inch rebar I have material loss underneath and slightly above the rebar and one 6 inch section and the flanges came apart as you could see on the underside. I would love to know if this could be repaired and how?

You sure you posted the correct photo. This looks like wood framing, not concrete plank.