QUESTION

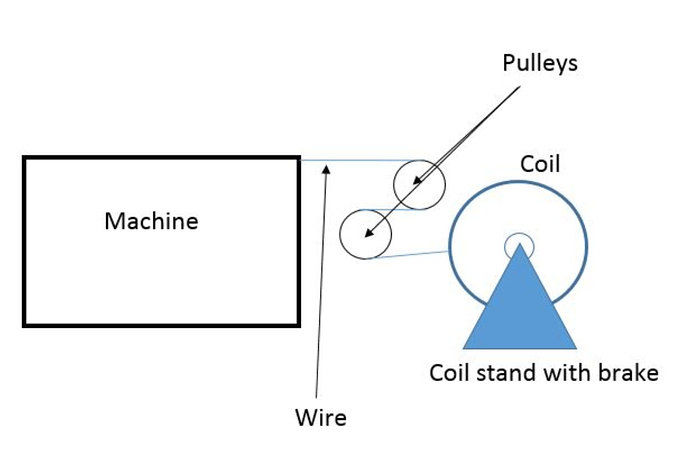

I’m looking to control the tension in a steel wire that is being unwound from a coil, passes over two pulleys and delivered into a machine. The power for the unwind of the coil is coming from a pull-thru unit in the machine and not driven from the coil, however, the coil does have a built in pneumatic brake.

I would like to control the tension in this wire by using both a pulley that is spring-loaded or pneumatic, that will provide a tension reading to the brake and thus, controlling the tension of the unwinding wire.

So far i am using a pulley that is mounted onto a horizontal gas spring, and this allows some self-adjusted for the tension. I would like to set up a small rig using a pneumatic cylinder that will provide some kind of reading for the tension, Are these available to buy as one unit? or will i have to mount some kind of positional sensor alongside this? Also, not having much experience with controls systems, i would like to create some kind of feedback loop to the coil brake, but im not sure the best (and most simple way) to achieve this.

We have a tug of war in play here, one end of the strand is being pulled through the machine while the other end is wound many times around a core that is feeding the machine. This is a raw wire material we have delivered. So when we have a fresh coil of wire feeding the machine, there is high tension in the wire as it requires a much greater torque to rotate the heavy mass, as it builds up momentum less force is required, as opposed to when we have used half the coil the mass is much lighter, and when there are machine stops this process repeats…etc…Our coils are feeding wire into the machine for a few hours so this variable tension is very difficult to manage and causes deformation in the wire.

The proportionality between the tension and the extension/compression of the cylinder rod was something I was going to take advantage of to feedback to the brake on the coil. Maybe a load cell is something that would perform better in this application? I have this in mind when thinking of a load cell and pulley… http://www.montalvo.com/pulley-load-cells-wire-filament-cable-ribbon/

Here is a diagram of what I’m talking about:

REPLIES

Jboggs

It appears the ultimate “source” of your problem is the inability of your process to deal with the variable tension levels required to fully unwind the feed spool. You need an isolating mechanism between the feed spool and your processing function that is designed to pull wire from the feed spool at a given rate regardless of the tension required and then feed that wire out at that same rate. Your take-up on the other end of the process should operate in a tension mode so it is always pulling at the same tension. That isolating device will probably include what is commonly referred to as a “bridle” arrangement, wherein the strand is wrapped around two or more driven pulleys (similar to those shown in your diagram) with wrap angles large enough to create a significant amount of friction between the strand and the pulley. That friction is the “isolator” that separates the variable tension level upstream at your pay-out from the constant tension level downstream in your process.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=419158

Above is a snippet.