QUESTION

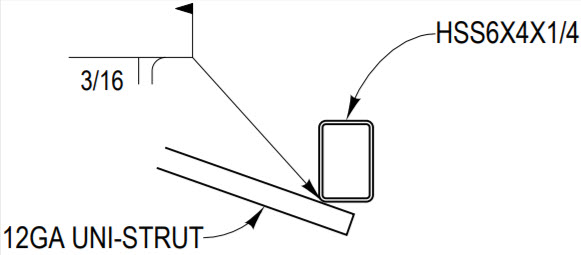

What do you guys think about this detail? The legs of the unistrut are facing downwards.

The load is only about 150bs. The existing unistruts are already welded in this manner so I am trying to match them.

I could add some small clip angles, if needed.

Below is my detail:

REPLIES

CANPRO

What if one of the holes in the top side of the unistrut line up with the corner of the HSS? Hopefully when installing they would cut the length such that this isn’t a problem…but you know how that can go.

If you’re really concerned about the weld quality on the unistrut, you could add a small plate (a bit wider than the unistrut) between the unistrut and the HSS - weld the plate to the unistrut on the ground/in the shop where the legs hit the plate, and then weld the plate to the HSS as you have detailed.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=449246

Above is a snippet.