QUESTION

I need to know your opinion on the concept we are developing for upending a monopile .

This is an Offshore Lifting on a vessel.The Vessel I’m showing has only one crane and its capable of lifting a long pile vertically. This long pile is a one time installation, so we are not looking to pay IHC or someone a huge sum.

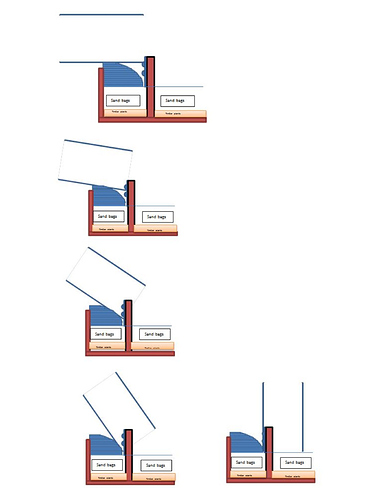

I have attached a schematic dig of the upending procees.

We are planning to use a bearing pad of elastomers or sand bags for bearing of the pile.

The length of pile = 75m

Dead Load = 350T

Dia = 4.5m

REPLIES

Ussuri

The use of shear key to pull the pile against is a common way of doing it for offshore pile upending. I haven’t seen it done with piles as large as yours but would assume the process would be similar. To upend a 75m pile using a single crane is going to require a lot of hook height, its a big crane.

Normally the end of the pile is held captive and there are bumper bars/ guides to ensure the pile does not become uncontrolled and impact something or someone. The guides ensure the pile can only move in a single plane.

A lot of the time you will see people using timber where you have an elastomer. It gets ripped to pieces pretty badly. However, at your weight timber might not be suitable.

You can hire ‘shoes’ and other upending frames from the likes of IHS.

Another option for subsea piles is to lift horizontal, deploy to the seabed and then upend subsea.

SOURCE

https://www.eng-tips.com/viewthread.cfm?qid=325345

Above is a snippet.